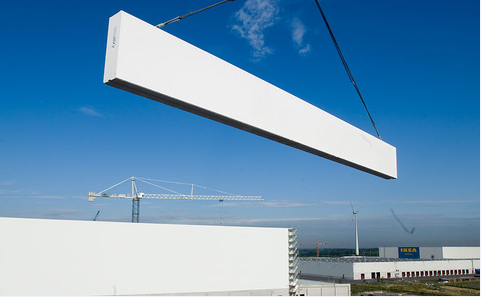

1. What’s ALC panel?

ALC(Autoclaved Lightweight Concrete), which is composed of silica sand, cement, aluminum, lime as the main raw material, inside with two-way steel mesh with anti-rust and anti-corrosion treatment, after high temperature, high pressure steam , formed porous concrete panel, is a superior new building material.

Panel can be divided to wall panels, external wall panels, roof and floor panels according to its use. Reinforcing of each panel are based on the design load, material thickness, length, etc. Thickness is usually supplied from 50mm ~ 300mm, with 25mm intervals , the maximum length is 6 m (>=150mm thick).

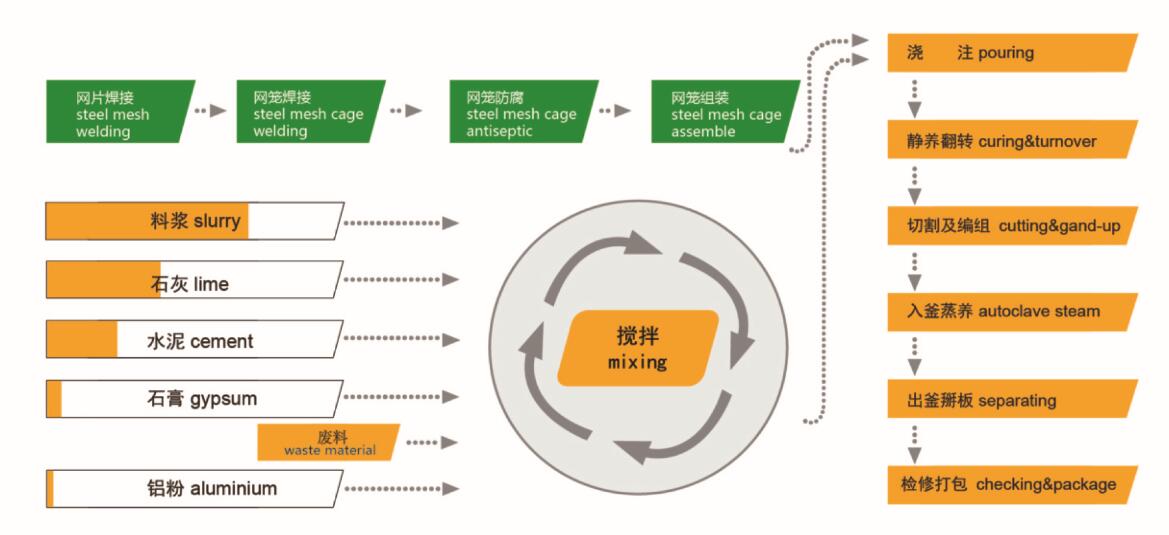

2. Production process description

★ Dongyue has its own AAC block, ALC panel and sand-lime three in one plant; with rich experience in manufacturing equipment and AAC plant management, we can provide our customers with latest technical support and management experience output timely;

2.1 Raw material storage

Sand ,cement,lime, gypsum,aluminum paste should be stored separately, transport them to the suitable position when use. Cement should be stored in the closed silo. Lime after grinding should be stored in the closed silo. Aluminum or aluminum paste must be stored hermetically, and can not be longer than 6 months.

2.2 Raw material dealing

Put sand or fly ash to the ball mill to mill (wet type) via the conveyor belt. After milling, the slurry will be pumped into the slurry storage tank by slurry pump.

2.3 Preparation and antiseptic treatment of reinforcement cage

A.Straighten the curled reinforced and stretched to the desired diameter, then cut into different lengths.

B. Use the steel mesh welding machine welded into a mesh in accordance with the arrangement of different lengths.

C.The two welded mesh, use H film, and then welded into a cage.

D.Cage needs embalmed and drying ,then can be used in the production process.

E.The crane will put the cage in the mold after pouring .

2.4 Batching, Mixing, Pouring

Lime, cement will be conveyed by screw conveyor to the dry powder measure scale. Slurry will be conveyed by slurry pump to the slurry measure scale. Then the power and slurry will be mixed together in the pouring tank, after 5-6 minutes, they will be poured into the mold box.

2.5 curing &cutting

The slurry in mold box will stay in the curing room for two or three hours .In curing room, the temperature should keep 50~70℃. After two or three hours, the slurry will be hard and become to be a block, but like a cake, which is hard but a little soft. First, the cake will be pulled out of curing room with the mold box together and the steel cage crane will pull the drill rod out of the cake. And then the cake will turn in the sky for 90 degree by reversal crane and then be put on the cutting cart. The cutting cart will move to the position of cutting machine, to finish side cutting, level cutting and vertical cutting.

2.6 Autoclave

The cake after cutting , will be put on the steam trolley. There are two cakes on one set steam trolley. Six or seven steam trolleys will be dragged into autoclave and stay for 10 to 12

2.7 Finished product dealing

After 10 to 12 hours, the block will be pulled out of autoclave by hoist machine. Finished block can be separated by labor or machinery. If you choose machinery, the process is as following:

Transport Crane will lift the block with side pallet to the rollers that can move. Block move to the position of separating machine. Separating machine will separate the blocks one layer by one layer. At last, Another crane will carry the block to the packing position. Side pallet will return to the position of reversal crane and group a new mold box and use again.

3. ALC panel application Examples

3.1 Inner Wall panel applications

3.2 Out Wall panel applications

3.3 Roof board applications